Taking care of your plant will guarantee performance that stands the test of time.

Whether routine or emergency,

we’re always here to help

For added peace of mind, we can offer maintenance contracts. These contracts cover regular preventive maintenance as well as equipment repairs and replacements.

With specialised technicians located throughout France, we can also provide swift ad-hoc services when requested.

We use self-contained breathing apparatus

when carrying out maintenance work

Cleaning

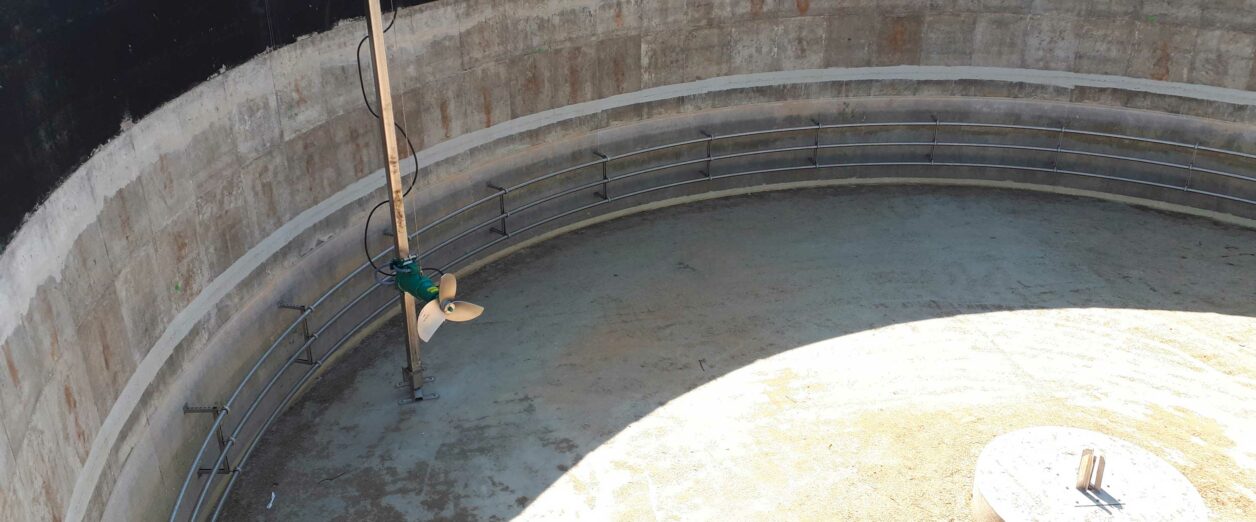

Biomethane plants should be cleaned every five to ten years depending on the type of plant and the feedstock used. We carry out quick and simple cleaning using a crane system with a clamshell grab to remove the material.

To ensure everyone’s safety, it is vital that any SCBA maintenance work is carried out with maximum preparation and protection. Accordingly, we follow a set procedure when cleaning digesters and other tanks (storage pits).

We can also use a four-turbine excavator if access is restricted (e.g. where the tank has a concrete roof with manhole access only).

Repairing submersible agitators

In the event that a submersible agitator gets clogged with digestate or the lifting device breaks, we can unblock it or retrieve it and attach a new chain without halting production or emptying the tank.

Spare parts available all over France and delivered within 24 hours

Call us on:

+33(0)2 85 67 00 40

Our advisers are available Monday to Friday, from 8 am to 6 pm. They can help you choose the correct parts and schedule a maintenance visit where necessary.

Available brands

Safety is everyone’s concern

Risk prevention

Equipment

To guard against risks, it is important to first identify them: gas, fire, explosions, operating machinery, etc. We equip everyone in the team with the safest and most appropriate clothing, protective equipment and tools.

Purchasing safety equipment

Conscious of your safety too, we offer a range of certified equipment that can be purchased directly through our customer area :

• SCBA masks

• Purifying filter units

• 4 gas multi gas detectors

• Half-mask respirators

• Voltage detectors

• Gloves (PPE)

Training and accreditations

Aside from providing equipment, we also train our co-workers so they are properly accredited and can deal with any eventuality.

• Electrical authorisation

• Training in handling and changing parts in ATEX and ATEX 2 equipment (through certifying body INERIS)

• Training in operating aerial lifts and telescopic handlers

• Training in the use of self-contained breathing apparatus (SCBA)

• Workplace first aid training

• Fire extinguisher training

• Working at height training

• Scaffolding inspection authorisation